Last updated: August 13, 2020

Last month, I had the opportunity to listen to Jeff Chapin, the co-founder and Chief Product Officer at Casper, talk at HustleCon 2016. (You may also want to check David Bladow from BloomThat speaking notes at HustleCon 2016)

Introduction

Casper is a company that’s all about working to give us a better night’s sleep. The business began with the very foundation of a good night’s rest – buying a mattress – and to simplify the process even further, Casper decided they would sell just one product to all customers.

People loved it.

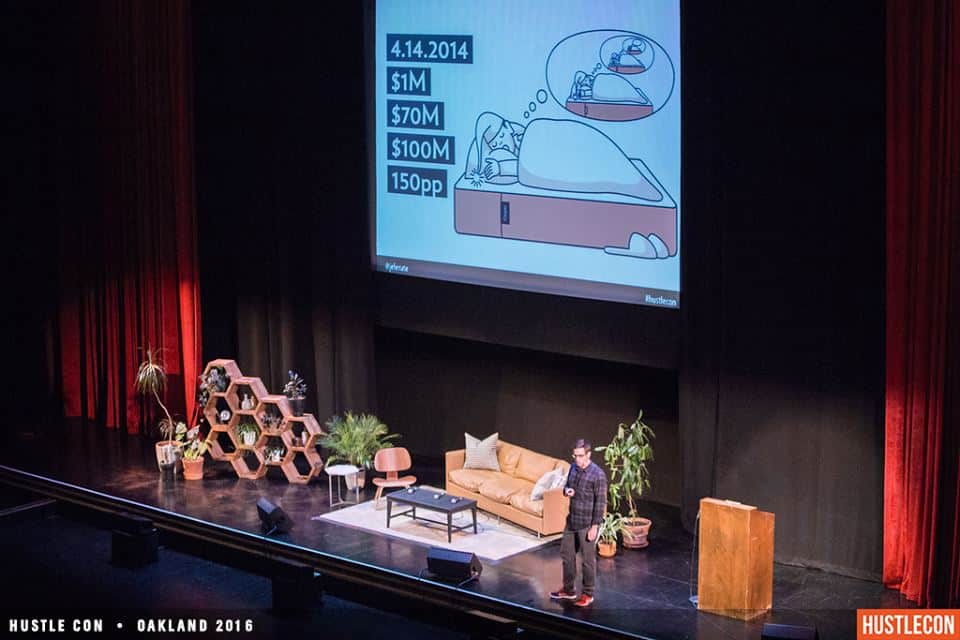

As of April 14, 2016:

- Casper generated $1 million in revenue in their first month

- The company received $70 million in funding

- The business grew to 150 employees.

But that incredible explosion of growth didn’t come without its own set of challenges.

The big problem?

Casper grew so fast, the company couldn’t meet their sales demands. On the first day of business, 139 beds sold. The catch? Only 100 were in stock.

By October of their first year, their backlog was now up to 35 days – and it would take 18 months for Casper to work its way out of the backlog. (Casper has only been in business for 25 months – that’s 72 percent of the company’s existence spent in backlog.)

Even today, the company will experience an occasional period of high volume orders and end up back in backlog.

“We got product, marketing, brand and value proposition right,” Chapin explained.

“We missed on supply chain. We did not hire an Operations person for the first year. We had no idea what we were doing.”

Lessons From Casper’s Early Months

1: Make the right (first) impression. You’ll live with it for a while.

Be deliberate in how you dress, how you arrive, and what you talk about.

2: Everyone will say they can do everything. It’s not true.

Walk the manufacturing line, step by step. Are they actually already doing everything they say they can do? Look for:

- Standard Operating Procedures

- QA checks

- QA people

- Inventory Management tools and methods

3: Join good company. They’ve done a lot of work for you.

Find suppliers that have done good work for good companies.

Example: If we find a supplier who has done work for Ikea, we know they’re going to be on top of their shit.

But how do you do that?

- Ask for list of clients.

- Ask for their testing/inspection criteria.

- Ask for sample product specifications.

4: If you want to be green, start green.

Being eco-friendly is nice, but not very profitable.

5: Suppliers are not your friends, even though it seems like they are.

Jeff’s rules to live by when it comes to suppliers:

- Buy your own dinner.

- Don’t get drunk.

- If in Asia, no karaoke.

- Know that you’re outgunned. Their sales team is soooo experienced.

Read this book: Influence: The Psychology of Persuasion.

6: Vendor Agreements, get one!

Build in:

- IP Ownership

- Exclusivity

- Data Sharing

- Inventory Management

- Change of control

- Three of our main suppliers were purchased by a single private equity firm recently. Having a change of control in our vendor agreement allows us to re-negotiate.

- Chargebacks

- Warranty

- Pricing transparency

7: Price to an index. Price in Volume.

We neglected to include volume discount pricing with our vendors. We haven’t saved any money with recent raw material cost declines. So we can’t profit off it or pass that savings to our customers.

8: Hire internal ops expertise early. It pays for itself.

If you’re going to manufacture a physical product, you need this.

Example: We ship millions of dollars with FedEx each year. We had a third-party doing our Accounting. When we hired an Analyst to review our FedEx and other bills, we found a mattress that we shipped to Fiji supposedly for $1400. We never did that, no way, no chance. We estimate there are going to be up to $300,000 in savings that we’ll get from digging through bills and doing chargebacks.

- Sourcing – to find multiple suppliers from day one

- Logistics – to keep track of how product moves

- Warehousing – to always know what’s in inventory

- Planning

- Analyst

Conclusion

If you make a promise, you have to deliver on the promise. As a startup, people will forgive you if things are bumpy for a little while, but eventually your time will run out. It’s critical to hire an Ops person soon to help you get ahead.